What makes something Explosion Proof?

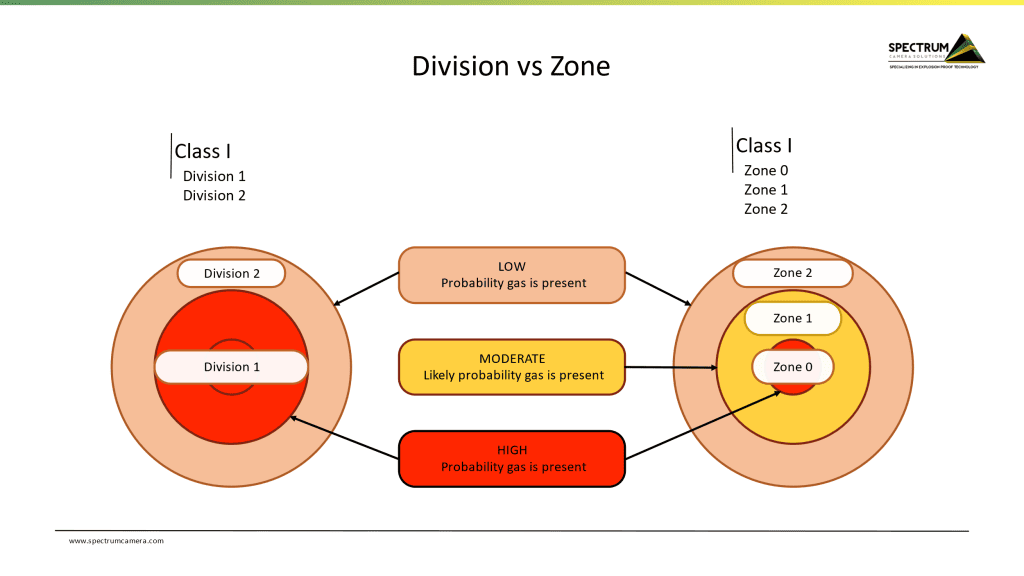

Explosion-proof certifications are crucial for ensuring the safety of electrical and electronic equipment used in environments where there is a risk of explosive atmospheres. These certifications often involve classifying hazardous locations into specific classes and zones, providing a standardized framework for equipment design and installation. The two primary classification systems are the Class/Division system (common in North America) and the Zone system (common in Europe and other parts of the world).

Here’s an overview of both systems:

Class / Division System I, II, III and explanation

a. Class:

Classes refer to the general nature of the hazardous material present in the atmosphere. The three main classes are:

Class I – Flammable Gases and Vapors:

Division 1: High likelihood of the hazardous material being present under normal operating conditions.

Division 2: The hazardous material is not likely to be present in an explosive concentration under normal operating conditions.

Class II – Combustible Dusts:

Division 1: Presence of combustible dust is expected during normal operating conditions.

Division 2: Combustible dust is not likely to be present in an explosive concentration during normal operating conditions.

Class III – Ignitable Fibers and Flyings:

Division 1: Ignitable fibers and flyings are present under normal operating conditions.

Division 2: Ignitable fibers and flyings are not likely to be present in an explosive concentration under normal operating conditions.

b. Division:

Divisions further specify the likelihood of the hazardous material being present. Division 1 indicates a higher risk, while Division 2 signifies a lower risk.

Zone System:

a. Zone:

Zones categorize hazardous locations based on the frequency and duration of the presence of explosive atmospheres.

The three main zones are:

Zone 0: Explosive atmosphere is present continuously or for long periods.

Zone 1: Explosive atmosphere is likely to occur during normal operations.

Zone 2: Explosive atmosphere is not likely to occur during normal operations but may occur infrequently and for a short duration.

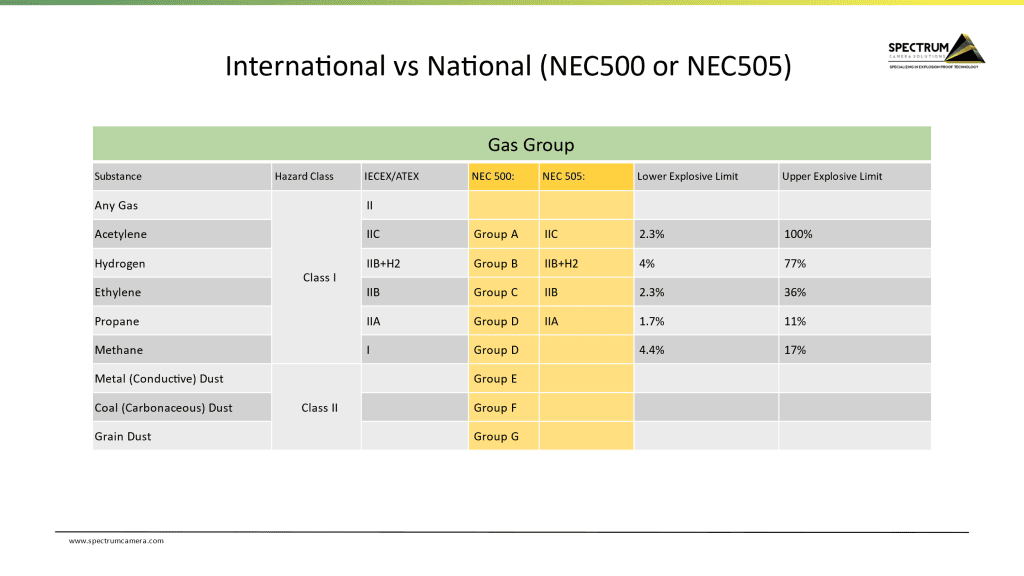

b. Gas Groups:

Hazardous gases are categorized into groups based on their ignition properties. There are three groups: IIA, IIB, and IIC, with IIC representing the most hazardous gases.

- Group A: Acetylene

- Group B: Hydrogen

- Group C: Ethylene

- Group D: Propane & Methane

- Group E: Metal Dust

- Group F: Carbonaceous Dusts

- Group G: Combustible Dusts

c. Temperature Classes:

Temperature classes indicate the maximum surface temperature that the equipment can reach without igniting the surrounding atmosphere. The classes range from T1 (highest temperature) to T6 (lowest temperature).

Conclusion: Ensuring Safety through Standardization

Both the Class/Division and Zone systems provide a standardized approach to assessing and mitigating the risks associated with explosive atmospheres. Understanding these classifications is essential for selecting and installing explosion-proof equipment in a manner that aligns with safety standards and regulations applicable to the specific region or industry.

Understanding Explosion-Proof Cameras- What is it?

An explosion-proof camera is a specialized surveillance device designed to operate safely in potentially hazardous environments where there is a risk of explosions due to the presence of flammable gases, vapors, or combustible dust. These cameras are constructed with features that prevent them from serving as an ignition source and minimize the risk of causing an explosion in such environments. Here are key characteristics and features of explosion-proof cameras

Robust Enclosure:

Explosion-proof cameras are housed in robust and durable enclosures designed to withstand the pressure generated by an internal explosion. The enclosure is constructed to contain the explosion within the camera housing, preventing it from propagating to the external environment.

Certification and Compliance:

Explosion-proof cameras are typically certified and comply with industry standards and regulations, such as those set by organizations like Underwriters Laboratories (UL) or the International Electrotechnical Commission (IEC). These certifications confirm that the camera meets specific safety requirements for use in hazardous environments.

Protection Against Environmental Elements:

These cameras are designed to withstand harsh environmental conditions, including exposure to corrosive substances, extreme temperatures, and physical impact. This protection ensures the longevity and reliability of the camera in challenging industrial settings.

High-Quality Imaging:

Despite the focus on safety features, explosion-proof cameras are equipped with high-quality imaging technology to capture clear and detailed video footage. This allows them to fulfill their surveillance and monitoring functions effectively. Some camera models also utilize artificial intelligence for enhanced safety and process safety focus.

These cameras are commonly used in industries such as petrochemical, oil and gas, chemical processing, mining, and manufacturing, where the risk of explosive atmospheres poses a significant safety concern. Explosion-proof cameras play a crucial role in maintaining surveillance capabilities in these high-risk environments without compromising safety standards.

About Spectrum Camera Solutions:

Spectrum Camera Solutions manufactures a full range of globally certified Explosion Proof cameras to monitor any hazardous area. Founded in 2012, Spectrum Camera Solutions has an unparalleled background as a world leader in hazardous-area vision systems featuring explosion-protected cameras. Our systems help monitor process areas, security, and safety, and our innovative Explosion Proof camera housings are made from durable materials and innovative engineering to ensure operational excellence in harsh environments. Our cameras are Made In Texas and we keep models in stock that are ready to ship.

Current manufacturers offered:

- Spectrum – Axis Explosion-Proof Camera

- Spectrum – Bosch Explosion-Proof Camera

- Spectrum – Avigilon Explosion-Proof Camera

- Spectrum – Motorola Explosion-Proof Camera

- Spectrum – Panasonic Explosion-Proof Camera

- Spectrum – Pelco Explosion-Proof Camera