Unveiling Blue Ammonia: Revolutionizing Energy Production

In the quest for sustainable energy solutions, blue ammonia has emerged as a promising player, capturing the imagination of industries worldwide. This innovative fuel source represents a significant shift towards cleaner energy production, offering a pathway to meet the growing global demand for ammonia-based products. Let us delve into the intricacies of blue ammonia production, explore its burgeoning market, and underscore the critical importance of employing explosion-proof cameras for ensuring process safety.

Understanding Blue Ammonia

Ammonia, a compound comprised of nitrogen and hydrogen, has long been utilized in various industrial processes, including fertilizers, pharmaceuticals, and refrigeration. Traditionally, ammonia production relied heavily on fossil fuels. However, the advent of blue ammonia heralds a new era in sustainable energy.

Blue ammonia is produced through a process called ‘blue hydrogen‘, wherein hydrogen is derived from natural gas or renewable sources like electrolysis. The resultant hydrogen is then combined with nitrogen sourced from the air through the Haber-Bosch process, yielding ammonia. What sets blue ammonia apart is its reduced carbon footprint, achieved through carbon capture and storage (CCS) or carbon capture and utilization (CCU) technologies. By capturing and storing or repurposing carbon emissions generated during production, blue ammonia significantly mitigates its environmental impact compared to conventional methods.

The Rapid Growth of Blue Ammonia Market

The global shift towards decarbonization and renewable energy sources has fueled the rapid expansion of the blue ammonia market. Governments, corporations, and environmental advocates alike are increasingly embracing this clean energy solution as a pivotal step towards achieving carbon neutrality.

Key factors driving the growth of the blue ammonia market include:

- Environmental Imperatives: With mounting concerns over climate change, there is heightened pressure on industries to adopt sustainable practices. Blue ammonia represents a tangible solution to reduce carbon emissions across diverse sectors while meeting energy demands.

- Policy Support: Governments worldwide are implementing stringent regulations and incentivizing the adoption of low-carbon technologies. Subsidies, tax credits, and emissions trading schemes are fostering a conducive environment for the proliferation of blue ammonia production facilities.

- Technological Advancements: Ongoing advancements in hydrogen production, carbon capture, and storage technologies are making blue ammonia production more efficient and cost-effective. Continued research and innovation are driving down production costs, making blue ammonia increasingly competitive in the energy market.

Ensuring Process Safety with Explosion-Proof Cameras

In the realm of industrial processes, safety is paramount. The production of blue ammonia involves numerous complex operations, including high-pressure reactions and volatile chemical compounds. As such, ensuring the safety and integrity of production facilities is imperative to prevent accidents and mitigate potential hazards.

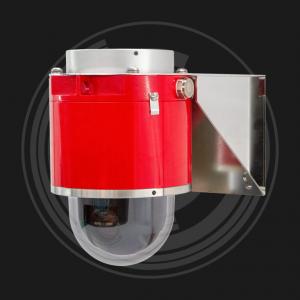

Explosion-proof cameras play a pivotal role in enhancing process safety within blue ammonia production facilities. These specialized cameras are engineered to operate in hazardous environments where the risk of explosions due to flammable gases or combustible dust is prevalent. By employing explosion-proof cameras, operators can:

- Monitor Critical Processes: Explosion-proof cameras enable real-time monitoring of key production processes, allowing operators to identify potential hazards and take preemptive measures to avert accidents.

- Enhance Situational Awareness: With high-definition imaging capabilities, explosion-proof cameras provide clear visibility even in challenging conditions, enabling operators to detect abnormalities or anomalies promptly.

- Facilitate Remote Surveillance: Inaccessible or hazardous areas within production facilities can be remotely monitored using explosion-proof cameras, ensuring continuous surveillance without compromising personnel safety.

- Comply with Regulatory Standards: Compliance with stringent safety regulations and standards is essential for industrial operations. Explosion-proof cameras are designed and certified to meet regulatory requirements, offering peace of mind to facility operators and regulatory authorities alike.

In conclusion, blue ammonia represents a paradigm shift towards sustainable energy production, offering a viable solution to meet energy demands while fostering environmental stewardship. As the market for blue ammonia continues to expand, ensuring process safety remains paramount. The integration of explosion-proof cameras exemplifies a proactive approach towards mitigating risks and safeguarding personnel and assets within blue ammonia production facilities, thereby paving the way for a cleaner, greener future.

About Spectrum Camera Solutions:

Spectrum Camera Solutions manufactures a full range of globally certified Explosion Proof cameras to monitor any hazardous area. Founded in 2012, Spectrum Camera Solutions has an unparalleled background as a world leader in hazardous-area vision systems featuring explosion-protected cameras. Our systems help monitor process areas, security, and safety, and our innovative Explosion Proof camera housings are made from durable materials and innovative engineering to ensure operational excellence in harsh environments. Our cameras are Made In Texas and we keep models in stock that are ready to ship.

Current manufacturers offered:

- Spectrum – Axis Explosion-Proof Camera

- Spectrum – Bosch Explosion-Proof Camera

- Spectrum – Avigilon Explosion-Proof Camera

- Spectrum – Motorola Explosion-Proof Camera

- Spectrum – Panasonic Explosion-Proof Camera

- Spectrum – Pelco Explosion-Proof Camera