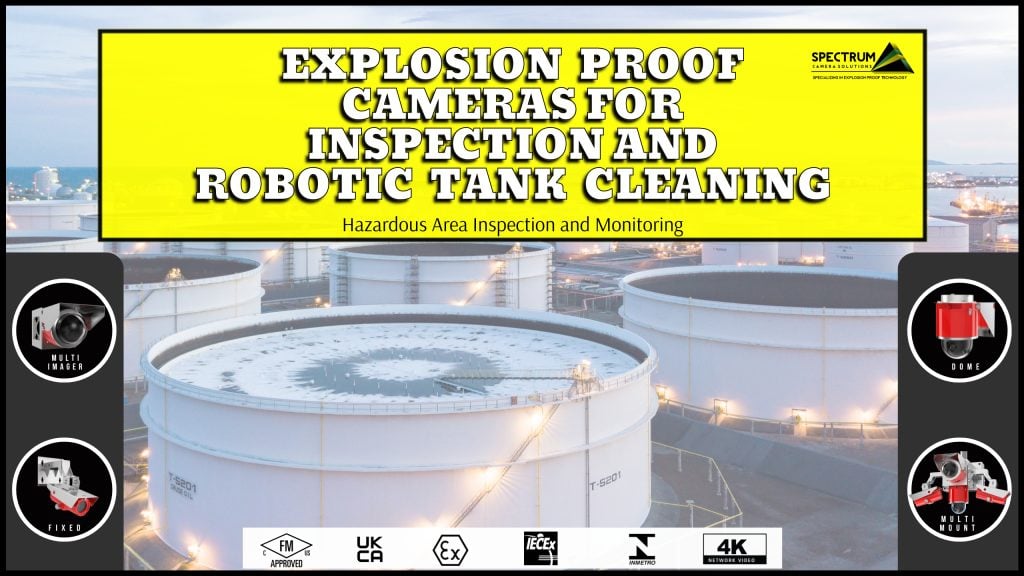

In the realm of oil and gas refining and petrochemicals, safety, efficiency, and precision are paramount. With the sector constantly evolving, embracing technological advancements has become imperative to stay ahead of the curve. One such revolutionizing trend is the rapid adoption of robotics for inspection and cleaning tasks within refineries and petrochemical plants. This transformative shift not only streamlines operations but also significantly enhances safety standards. However, to ensure optimal safety in hazardous environments, the integration of Class I Division 1 explosion-proof cameras is paramount.

Embracing Robotics: Revolutionizing the Industry

Traditionally, inspection and cleaning processes in oil and gas facilities have been labor-intensive and often hazardous for workers due to the presence of volatile substances and challenging operating conditions. However, the advent of robotics has ushered in a new era of efficiency and safety. These specialized robots equipped with advanced sensors, cameras, and AI capabilities can navigate complex environments, identify defects, and perform cleaning tasks with unparalleled precision without having personnel having to enter confined spaces.

Robotic inspection and cleaning offer several advantages over traditional methods:

- Enhanced Safety: By deploying robots, companies can significantly reduce the exposure of human workers to potentially hazardous conditions, thereby minimizing the risk of accidents and injuries.

- Increased Efficiency: Robots can operate 24/7 without fatigue, leading to faster inspection and cleaning cycles and minimizing downtime in critical operations.

- Cost Savings: While the initial investment in robotics may be substantial, the long-term cost savings in terms of reduced labor costs, enhanced productivity, and minimized maintenance expenses are considerable.

- Data-Driven Insights: Robotics equipped with advanced sensors and cameras can capture vast amounts of data during inspection and cleaning processes. This data can be analyzed to identify trends, predict equipment failures, and optimize maintenance schedules, leading to improved asset management and operational efficiency.

Ensuring Safety with Class I Division 1 Explosion-Proof Cameras

While the benefits of robotics in the oil and gas sector are undeniable, operating in hazardous environments necessitates stringent safety measures. One crucial component of ensuring safety is the use of Class I Division 1 explosion-proof cameras.

What are Class I Division 1 Explosion-Proof Cameras?

Class I Division 1 refers to hazardous locations where flammable gases or vapors are present under normal operating conditions. In such environments, even a small spark can trigger a catastrophic explosion. Explosion-proof cameras are designed to mitigate this risk by containing any potential explosion within the camera enclosure, preventing it from igniting surrounding gases.

Benefits of Using Explosion-Proof Cameras with Robotic Tank Cleaning and Inspections:

- Mitigating Explosion Risks: In the event of a malfunction or electrical fault, explosion-proof cameras prevent sparks or heat from igniting flammable gases by containing any potential explosion within the camera enclosure, thereby preventing the risk of explosions in hazardous environments.

- Compliance with Safety Regulations: Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) mandate strict safety standards for operations in hazardous locations. Integrating explosion-proof cameras ensures compliance with these regulations, avoiding potential fines and penalties.

- Maintaining Operational Continuity: Remote monitoring of hazardous areas with Explosion Proof CCTV systems allow for an elevated level of safety when performing inspections and during cleaning projects. This allows for uninterrupted operations, preventing costly downtime and ensuring business continuity.

- Protecting Assets and Personnel: The use of explosion-proof cameras not only safeguards equipment and infrastructure but also protects the lives of personnel working in hazardous environments, reinforcing a culture of safety within the organization.

Conclusion

The rapid adoption of robotics for inspection and cleaning tasks in the oil and gas refining and petrochemical sector represents a significant paradigm shift towards enhanced safety, efficiency, and productivity. By leveraging advanced technologies such as robotics and integrating Class I Division 1 explosion-proof cameras, companies can navigate the complexities of hazardous environments with confidence, ensuring the well-being of personnel and the sustainability of operations in the face of evolving industry challenges. Embracing this technological evolution is not just a choice but a necessity for organizations striving to remain competitive and resilient in the dynamic landscape of the energy industry.

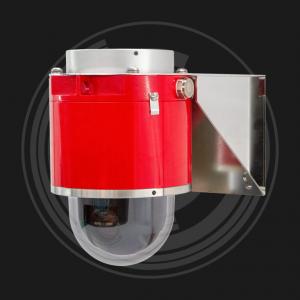

About Spectrum Camera Solutions:

Spectrum Camera Solutions manufactures a full range of globally certified Explosion Proof cameras to monitor any hazardous area. Founded in 2012, Spectrum Camera Solutions has an unparalleled background as a world leader in hazardous-area vision systems featuring explosion-protected cameras. Our systems help monitor process areas, security, and safety, and our innovative Explosion Proof camera housings are made from durable materials and innovative engineering to ensure operational excellence in harsh environments. Our cameras are Made In Texas and we keep models in stock that are ready to ship.

Current manufacturers offered:

- Spectrum – Axis Explosion-Proof Camera

- Spectrum – Bosch Explosion-Proof Camera

- Spectrum – Avigilon Explosion-Proof Camera

- Spectrum – Motorola Explosion-Proof Camera

- Spectrum – Panasonic Explosion-Proof Camera

- Spectrum – Pelco Explosion-Proof Camera