Confined space entry is necessary in various industries to perform essential tasks such as maintenance, inspection, cleaning, installation, and repairs. Confined spaces, including tanks, vessels, silos, vaults, and pipelines, are crucial for storing materials, conducting processes, and housing utility infrastructure. Workers enter these spaces to ensure the integrity, safety, and functionality of the equipment and structures. Typical jobs involve inspecting for damage or wear, removing residues or blockages, repairing structural components, and maintaining operational systems.

Regulation for Confined Space Entry in the USA

The regulation for confined space entry in the United States is governed by the Occupational Safety and Health Administration (OSHA) under 29 CFR 1910.146, titled “Permit-Required Confined Spaces” (PRCS). This regulation aims to protect workers from the hazards associated with entering and working in confined spaces.

Key Requirements of OSHA’s Confined Space Regulation (29 CFR 1910.146)

Definition of Confined Space:

- A space large enough for an employee to enter and perform work.

- Limited or restricted means for entry or exit.

- Not designed for continuous occupancy.

Permit-Required Confined Space (PRCS):

- Contains or has the potential to contain a hazardous atmosphere.

- Contains a material with the potential for engulfing an entrant.

- Has an internal configuration that could trap or asphyxiate an entrant.

- Contains any other recognized serious safety or health hazard.

Permit System:

- Develop and implement a written permit space program.

- Permits must specify the precautions and conditions for entry, including atmospheric testing and monitoring.

Hazard Identification and Control:

- Identify and evaluate hazards before entry.

- Implement measures to eliminate or control hazards.

Training and Communication:

Provide training to all employees who work in or near confined spaces.

Ensure communication between entrants, attendants, and supervisors.

Emergency and Rescue Procedures:

- Establish procedures for summoning rescue and emergency services.

- Ensure rescue personnel are trained and equipped.

Types of Common Vessels considered Confined Space Found in Oil and Gas Operations:

Tanks:

- Storage Tanks: Used for storing liquids, gases, or solids, such as fuel tanks, water tanks, and chemical storage tanks.

- Process Tanks: Used in industrial processes for mixing, reacting, or holding materials, like fermentation tanks in breweries or reaction tanks in chemical plants.

Vessels:

- Pressure Vessels: Contain gases or liquids at high pressure, such as boilers and autoclaves.

- Reactors: Vessels in which chemical reactions are carried out, often under controlled pressure and temperature conditions.

Robotics in Industry:

To mitigate these risks, many industries are adopting robotics and remote-controlled devices for confined space tasks.

The primary reasons for this shift include:

- Enhanced Safety: Robotics eliminate the need for human entry into hazardous environments, significantly reducing the risk of injury or exposure to dangerous conditions such as toxic gases, low oxygen levels, or structural collapse.

- Operational Efficiency: Robots can perform inspections, cleaning, and maintenance tasks more quickly and accurately than human workers. They can access areas that are difficult or impossible for humans to reach, ensuring thorough and regular maintenance.

- Cost-Effectiveness: The use of robotics reduces labor costs, minimizes downtime, and extends the lifespan of infrastructure through consistent and precise upkeep.

By utilizing robotic technology, industries can enhance safety, improve efficiency, and lower operational costs, all while ensuring that confined spaces remain in optimal condition for their intended use.

In both cases, Spectrum Camera Solutions hazardous area camera systems can aid in safe operations with remote monitoring.

The Crucial Role of Surveillance in Confined Spaces

A confined space can be more dangerous than other work areas for several reasons. It may contain or produce dangerous chemicals, gases, or vapors, and the limited openings can result in poor natural ventilation, allowing hazardous atmospheres to quickly build up. Regular monitoring methods might not only be inadequate but can also expose safety personnel to the same hazards faced by workers inside the confined space.

That’s why surveillance technology, especially video cameras, plays a crucial role. Cameras can monitor the interior of a confined space continuously and provide real-time feedback to teams on the outside. This can be critical for early detection of emergency situations, observing work progress, and ensuring compliance with safety protocols without endangering more lives.

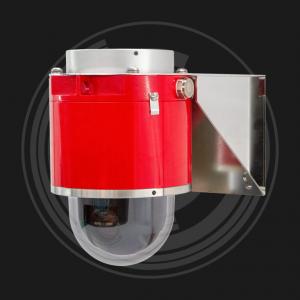

Explosion-Proof Cameras: A Necessity in Hazardous Environments

When it comes to environments that are prone to explosions due to the presence of flammable gases or dust, standard video surveillance equipment may not just be insufficient, but also a potential trigger for an explosion. Explosion-proof cameras, duly certified for use in explosive environments, are designed to contain any ignition or explosions within the device, preventing any external flammable atmosphere from igniting.

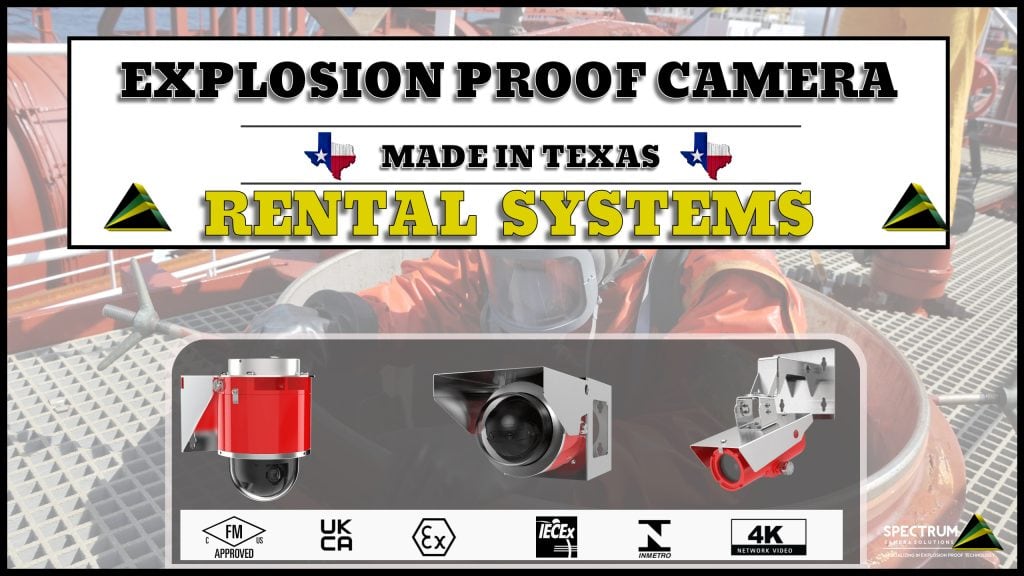

Spectrum Camera Solutions is a United States based manufacturer that specializes in Class I Division 1 cameras designed specifically for the toughest environments. Spectrum’s cameras meet stringent safety requirements and are robust enough to withstand the extreme conditions often found in these hazardous spaces especially when the atmosphere could contain flammable chemicals.

Spectrum Camera Solutions: Enhancing Safety with Rental Options

Recognizing the infrequent but crucial need for specialized equipment in confined space operations, Spectrum Camera Solutions has now expanded its offerings to include rentals. This move is particularly strategic for businesses requiring high-quality, reliable explosion-proof cameras but may not have the frequency of use that justifies a direct purchase. By offering rental services, Spectrum provides more companies with the opportunity to utilize high-standard safety equipment at a fraction of the cost.

Why Choose Spectrum’s Explosion-Proof Cameras?

Here are a few compelling reasons:

- Compliance with Safety Standards: Spectrum’s cameras comply with the most rigorous safety standards, ensuring they can safely operate in classified hazardous environments.

- High-Quality Visuals: Their cameras are not just safe but are also equipped with high-definition recording capabilities, ensuring that the visuals are clear and useful and perform well in low light environments.

- Ease of Use and Setup: Spectrum designs its cameras with the end-user in user-friendliness in mind, ensuring that teams can set up and operate them with minimum training.

- Versatility: The cameras can be used across various industries like oil and gas, chemical, petrochemical, tank storage, marine, wastewater treatment, and any other sectors involving explosive atmospheres.

Conclusion

When dealing with confined spaces, especially those that present an explosion risk, it is crucial to have robust safety practices backed by the right technology. Remote surveillance using explosion-proof cameras such as those provided by Spectrum Camera Charters offers a significant enhancement in safety, operational visibility, and incident responsiveness. With the added flexibility of renting these critical safety devices, companies can ensure the safeguarding of workers and compliance with industry regulations more cost-effectively and efficiently.

In light of the dangers confined spaces present, it isn’t just about observing operations; it’s about preserving lives and livelihoods. Investing in the right surveillance equipment, like the innovative solutions from Spectrum Camera Solutions, is not just a safety measure – it is a business imperative.

About Spectrum Camera Solutions:

Spectrum Camera Solutions manufactures a full range of globally certified Explosion Proof cameras to monitor hazardous areas. Founded in 2012, Spectrum Camera Solutions has an unparalleled background as a world leader in hazardous-area vision systems featuring explosion-protected cameras. Our systems help monitor process areas, security, and safety, and our innovative Explosion Proof camera housings are made from durable materials and innovative engineering to ensure operational excellence in harsh environments.